Mercury Control

Element 1 Engineering provides a variety or mercury control services from small scale activated carbon injection (ACI) systems for industrial boilers to combined ACI, BCA, and WFGD re-emissions solutions for all sizes of electric generating stations. E1E engineers were instrumental in pioneering activated carbon injection for mercury control and we continue to work with vendors and clients to make further advancements in mercury control technology.

Commercial Installations

Experienced engineers at Element 1 Engineering design custom tailored mercury control systems for a wide range of clients preparing to comply with EPA HAPS regulations in 2015. Element 1 Engineering can provide anything from a complete turn-key ACI installation to design of individual system components. Our engineers have years of experience addressing the special design considerations that are inherent with any material conveying system.

Our distribution manifold and injection lance design is industry recognized as the one of most efficient and reliable technologies for uniform in-duct activated carbon distribution. We source the best materials possible to provide reliable and robust systems.

Consulting

The engineers at Element 1 Engineering have been working in the utility industry for over 30 years. We have been instrumental in developing bag house technology for particulate control, SCR for NOX controls, DSI for SO3 and HCl removal, and ACI and BCA for mercury control. Many of clients find that systems installed to address one pollutant are often at odds with other pollution control objectives, or that control systems are just not performing as designed or promised. Our experienced staff of utility consultants can help our clients resolve many of the problems associated with these systems.

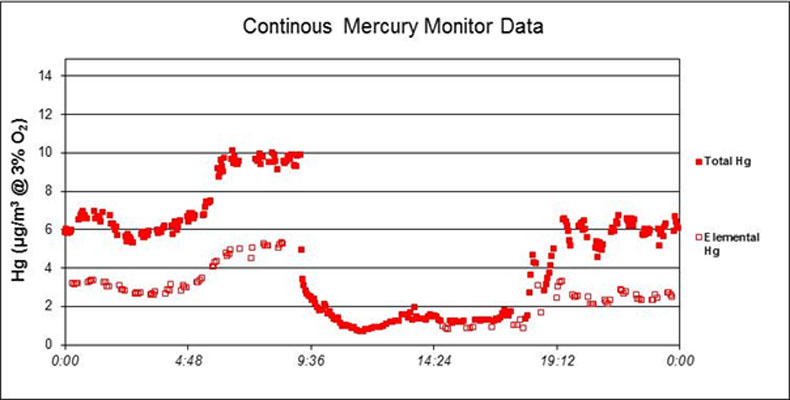

ACI System Optimization

With the multitude of activated carbon products on the market, it can be serious challenge choosing the correct product and feed rate for a particular boiler. Large material savings can be realized by choosing an optimized sorbent and minimizing overall sorbent usage. Potential loss of fly-ash sales and money wasted on over injection can be easily avoided by choosing the right sorbent and tuning injection rates under varying operating conditions. Utilizing E1E continous mercury monitors allows for real-time results for tuning and optimization, providing vastly superior resolution over Method 30B carbon traps. Element 1 Engineering has available several portable ACI systems, BCA systems, and continuous mercury monitors for tuning your ACI process.

Portable Sorbent Injection Systems

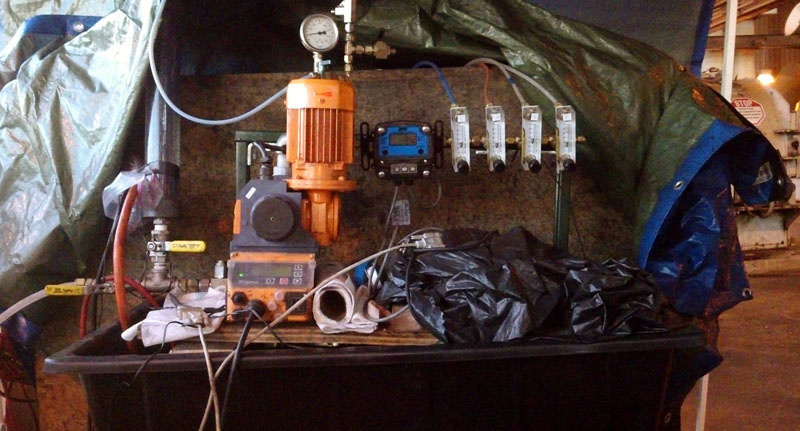

E1E owns four portable injection skids designed for handling 1000 lb super sacks of material. These systems incorporate real time loss of weight feedback for accurate injection rates. The injection skids have a relativeley small footprint and can be assembled in less than one day.

Boiler Chemical Additive Injection Systems

E1E operates several Boiler Chemical Additive (BCA) Injection systems designed to feed liquid 52% CaBr2 from either drums or totes. Our systems are designed to pump between 2 and 18 gallons per hour balanced between four injection locations.